Products

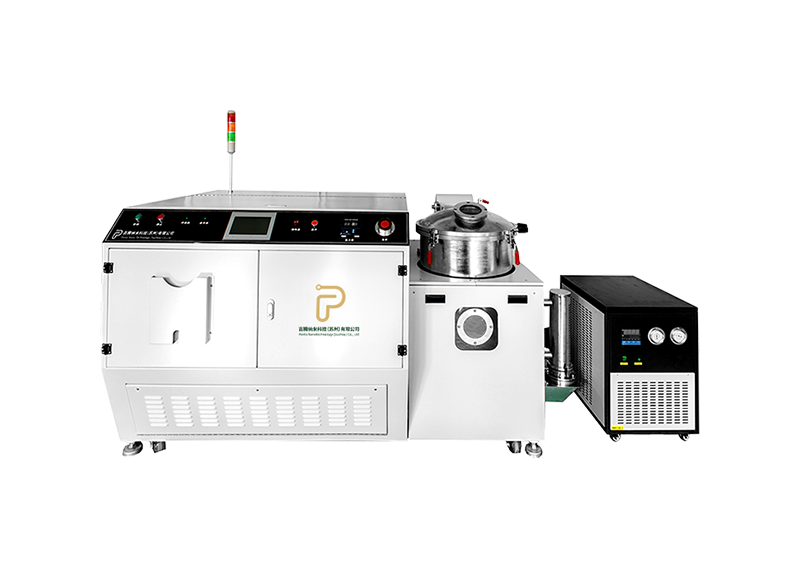

PTP-3HV

Classification:

CVD Vacuum Equipment

Model: PTP-3HV

Size of device: (L) 1859 * (W) 900 * (H) 1190 mm

Floor space: 7.243 ㎡

Chamber size: φ292*308 mm (Volume: 20.6L)

Effective chamber size: φ240*250 mm (Volume: 11.3L)

Electric quantity: 6000W

The appearance of the equipment is moderate with the volume of the vacuum chamber, covering an area larger than PTP-1V, and the film layer is uniform and high precision. It is suitable for a certain amount of research institutes, schools and other laboratories.

Product Description

Previous

PTP-5HV

Next

Application Area

FAQ

Blog

Knowledge

2025-09-24

The Benefits of Nano Coating in Modern Construction

The Benefits of Nano Coating in Modern Construction Table of Contents 1. Introduction to Nano Coating 2. What is Nano Coating? 3. Advantages of Nano Coating in Construction 3.1 Enhanced Durability 3.2 Water Repellency and Moisture Resistance 3.3 Self-Cleaning Properties 3.4 Energy Efficiency 3.5

Lern moreKnowledge

2025-09-22

Understanding the Benefits of PVD Vacuum Coating Machines for Aluminum Film Applications

PVD (Physical Vapor Deposition) vacuum coating machines play a crucial role in the production of aluminum films used in packaging and printing applications. These machines utilize advanced coating techniques to deposit thin layers of metal onto various substrates, significantly improving the properties of the coated material. Understanding the benefits and workings of PVD vacuum coating machines c

Lern moreKnowledge

2025-09-20

How a Parylene Coating Machine Enhances Waterproofing Materials for Superior Performance

How a Parylene Coating Machine Enhances Waterproofing Materials for Superior Performance Table of Contents 1. Introduction to Parylene Coating Technology 2. Understanding Parylene: Types and Characteristics 3. The Importance of Waterproofing Materials in Construction 4. How Parylene Coating Works 5. Advantages of Using Parylene Coating for Waterproofing 6. Applications of Parylene Coa

Lern more