Products

Dimensions:(L)600*(W)760*(H)1440mm

Floor Space:3.067m³

External Chamber Dimensions:Φ292*308mm(Volume:20.6L)

Internal Chamber Dimensions:Φ187*275mm(Volume:7.54L)

Power Rating:4000w

This device has an appropriate size in terms of both appearance and the volume of the vacuum chamber, with a small footprint. It is highly suitable for use in research institutions and school laboratories.

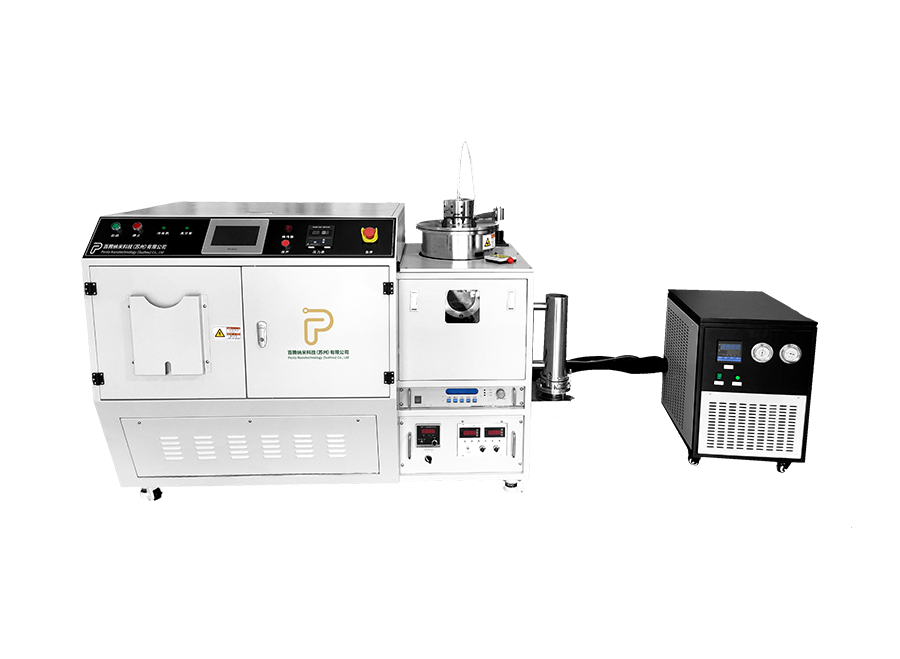

Small Parylene Coating Equipment

Dimensions:(L)1859*(W)900*(H)1190mm

Floor Space:7.243m³

External Chamber Dimensions:Φ292*308mm(Volume:20.6L)

Internal Chamber Dimensions:Φ240*250mm(Volume:11.3L)

Power Rating:6000w

The appearance of the equipment is moderate with the volume of the vacuum chamber, covering an area larger than PTP-1V, and the film layer is uniform and high precision. It is suitable for a certain amount of research institutes, schools and other laboratories.

Medium Parylene Nano Coating Machine

Dimensions:(L)2211*(W)1191*(H)1580mm

Floor Space:8.707m³

External Chamber Dimensions:Φ480*787mm(Volume:142.3L)

Internal Chamber Dimensions:Φ420*743mm(Volume:102.9L)

Power Rating:8000w

This device is lager in overall size than PTP-3V. It has stable uniformity and deposition rate, and it is suitable for coating processing of small and medium-sized enterprises.

What is Parylene?

It is a polyester protective material which is transparent and colourless. It is applied to the vacuum process at the room temperature, vacuum treatment pressure is carried out at 10-5torr or below, while the Parylene coating processing is formed at about 0.1torr. The thickness of the coating can be controlled between 1 and 100microns, which was developed by the American patent in the early sixties, and was firstly applied in the field of microelectronic components in US military printed circuit boards, aerospace and underwater launchers, it was included in the US military standard in 1972: MIL-I-46058C.

Vacuum Coating Equipment

Independent Research And Development, Design, Production, Customizable

SINCE 2001

Penta Nanotechnology (Suzhou) Co., Ltd

Penta Nanotechnology (Suzhou) Co., Ltd is a Singapore-owned enterprise which was founded in December 2001. It is located in Suzhou Industrial Park. Penta NanoTechnology concentrates on self-development, production and sales of Chemical Vapor Deposition Equipment, Microelectronic Equipment, Xenon Difluoride (Xef2) Etching Machine, Vacuum Degassing Furnace, Xenon Difluoride Raw material. Parylene Nano Material contains C powder, N powder, F powder, D powder and AF4 powder.

Contact Us Now

Address

Building23,Chuangtou Industrial Zone,Heshun Road,

North Block,Suzhou Industrial Park, Jiangsu Province,China 215122

CONTACT US

Knowledge

2026-02-26

Understanding Conformal Coating Machines: A Key to Enhanced Manufacturing Efficiency

Conformal coating machines are specialized equipment designed to apply protective coatings to electronic components. These coatings serve to enhance the reliability and longevity of electronic circuits by providing a barrier against moisture, dust, chemicals, and temperature variations. In today’s fast-paced manufacturing environment, understanding the functionality and advantages of conformal coa

Lern moreKnowledge

2026-02-22

Ultimate Guide to Waterproof Membrane Coating for Contractors Table of Contents What is Waterproof Membrane Coating? Importance of Waterproof Membrane Coating Types of Waterproof Membrane Coatings Application Techniques for Waterproof Membrane Coatings Advantages of Using Waterproof Membrane Coatings Common Challenges in Waterproofing Projects Best Practices for Contractors Freque

Lern moreKnowledge

2026-02-18

Exploring the Advantages of Solvent-Free Waterproof Coatings

In the realm of chemical engineering, particularly in the development of new chemical materials, solvent-free waterproof coatings stand out as an innovative solution. These coatings are designed to provide robust protection against water intrusion while eliminating the need for harmful solvents often found in traditional coatings. This advancement not only enhances performance but also aligns with

Lern moreGET IN TOUCH

If you are interested in our products or want to become our partner.

Please leave your contact information, our team will contact you as soon as possible.